Context: Stoller, a pioneering agro company based in Argentina, stands at the forefront of agricultural innovation. Their commitment to leveraging technology for more efficient and sustainable farming practices led to the development of a groundbreaking solution that combines IoT and AI. Stoller’s agricultural success hinges on their ability to harness the power of drones equipped with integrated AI to optimize irrigation. However, their primary challenge lay in establishing a serverless infrastructure that could seamlessly store and process critical data, aiding irrigation workers in identifying and tending to dry hectares.

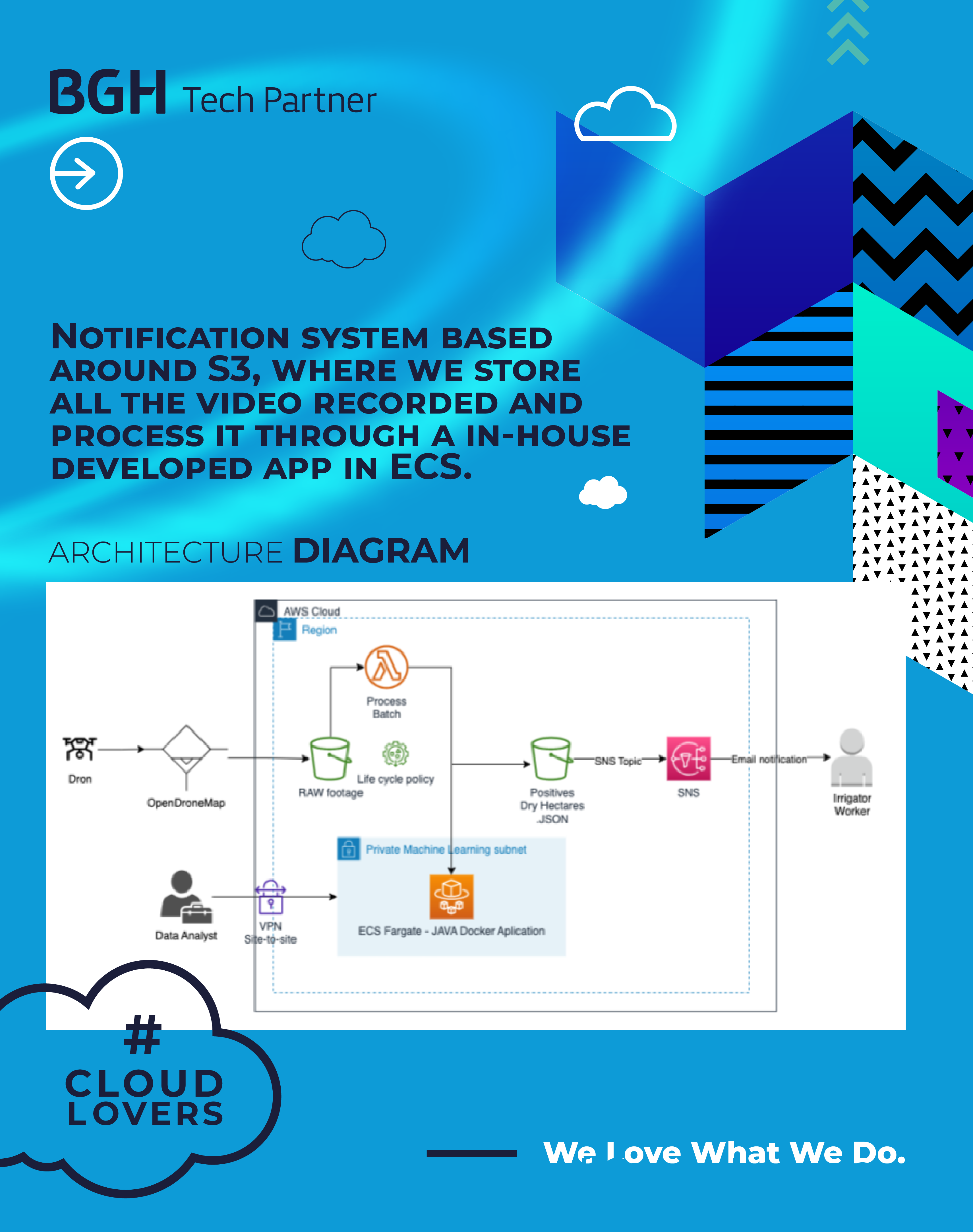

Challenge:The solution to this complex challenge came to fruition through AWS, with Stoller adopting a forward-thinking approach. At its core, Stoller’s innovative system relies on Amazon S3, a robust cloud-based storage service. Within S3, the system securely stores all video data recorded by their fleet of AI-powered drones, creating a comprehensive repository of valuable information.

Solution: To effectively process and analyze the vast amount of data generated by the drones, Stoller developed an in-house application hosted on Amazon Elastic Container Service (ECS). This application, powered by state-of-the-art algorithms, plays a pivotal role in identifying dry hectares in the expansive agricultural landscape. It tirelessly scans and interprets the recorded drone footage, enabling rapid and accurate assessment of the moisture content in each hectare.

However, the real magic happens once the algorithm detects a positive result, indicating a dry hectare in need of irrigation. Instantly, an automatic notification is generated and seamlessly sent to the irrigation workers with AWS SNS. This notification includes precise coordinates, ensuring that the agricultural workforce can swiftly and accurately locate and address the areas that require immediate attention. This real-time feedback loop streamlines the irrigation process, preventing water wastage, optimizing resource allocation, and ultimately enhancing crop yield and overall farm efficiency. AWS SNS allows Stoller to actively monitor and control their fields in real time.

By deploying AWS services as an integral part of their solution, Stoller has taken a giant leap toward revolutionizing precision agriculture in the region. The serverless infrastructure, driven by S3 and ECS, offers scalability, reliability, and the computational power needed to support their advanced AI-driven system. This innovative approach not only improves operational efficiency but also underscores Stoller’s commitment to sustainable, technology-driven farming practices.

In summary, Stoller’s use of AWS as a foundational element in their precision agriculture solution underscores the pivotal role of cloud computing and advanced data analysis in modern agro-industry. This collaborative effort between Stoller and AWS sets the stage for an exciting future, where cutting-edge technology meets agriculture, paving the way for increased productivity and more sustainable farming practices in Argentina and beyond.